USC Wins Port of Los Angeles Harbor Cup

The University of Southern California Trojans won the 17th running of the three-day, 10-race, coed Port of Los Angeles/Cal Maritime Harbor Cup Regatta after finishing in second place last year. As they were last year, they’ve been close, but this is their first victory in 15 years.

USC skipper Morgana Manti credits her team for the win. Their coach, Michael Segerblom, was celebrating more than the team’s first win since 2010, as earlier that day he became a grandfather for the first time, welcoming grandson Hans Paul Segerblom to the world.

Segerblom commended Cal Maritime, the Port of Los Angeles and Los Angeles Yacht Club, who together provide an opportunity for college students to participate in one-design big-boat offshore competition. For 17 years, he has witnessed teams’ receiving warm welcomes, meals, and accommodations. In addition, organizers cover charter fees so there is no cost to racers.

USC’s Manti, a junior studying screenwriting, credited Segerblom’s coaching and shared that four of the Trojan team members competed in last year’s regatta, and that experience also contributed to their win. “The starts were the most stressful part of the weekend. With 10 boats on the line and the wind shifts, it was definitely a challenge,” Manti said.

The eight-time winners of the cup, the University of Hawaii Rainbows, finished second. Two-time winners the College of Charleston Cougars took third.

In the small-world department, the USC team normally competes in FJs. Skipper Morgana Manti first sailed in Optis in her home country of Italy. The 2013 winning Long Beach Yacht Club Congressional Cup skipper, Simone Ferrarese, was her Opti coach. The 60th Congressional Cup, hosted by the Long Beach Yacht Club, is also coming up April 30 to May 4.

The Catalina 37s used for Harbor Cup are the same keelboats used in the Congressional Cup as well as the all-women’s Mayor’s Cup. In 2009, a very young Martine Grael competed in the Mayor’s Cup, and next weekend Grael will be skippering the Brazilian SailGP entry in SailGP Los Angeles, also held at the Port.

A special “Dockmaster Award” was presented by Junior Staff Commodore Ken Corry to the team taking the best care of the boats they sailed, with the Arizona Sun Devils earning the honor this year.

The 2026 regatta is tentatively planned for March 6–8, 2026.

You can see full results of the regatta here.

The Resourceful Sailor Makes a Strong Point

Long have the how-to pros like Don Casey preached the gospel of lining your fastener holes in wooden and foam-core decks and transoms with epoxy, to prevent water intrusion in case (or when) the sealants fail. I’ve followed their advice and techniques since my early boat-repair and -modification days. Filling holes with epoxy and not creating voids had its challenges. Even harder still was re-drilling the holes precisely where they needed to be, especially with multiple fasteners. I would often have to oversize the re-drills to get them to fit, risking thinning the walls of the epoxy I applied, thus potentially reducing its integrity. More than once, I felt it necessary to start over.

Then, through the local grapevine, I was introduced to a different approach to the same idea that addressed both difficulties mentioned above. This approach does not invalidate what the how-to pros have written about many times before. It only adds an amendment. In view of this, I will avoid excessive repetition and focus on the particulars, assuming you have researched (or will) the long-established best practices of epoxy-lining holes.

This Resourceful Sailor installment involves the use of G-10 tubes. G-10 is epoxy and fiberglass laminate cured under high pressure. It comes in various inner diameters and outside wall thicknesses. I’ve gotten mine from the handy online industrial supply store McMaster-Carr, but there are probably other vendors. Now, down to business.

A new storm jib for Sampaguita, a 1985 Pacific Seacraft Flicka 20, required blocks she didn’t have for proper leads and sail trim. Two strong points on each side of the deck were needed, and I was determined to retain Sampaguita’s “non-leaky” deck.

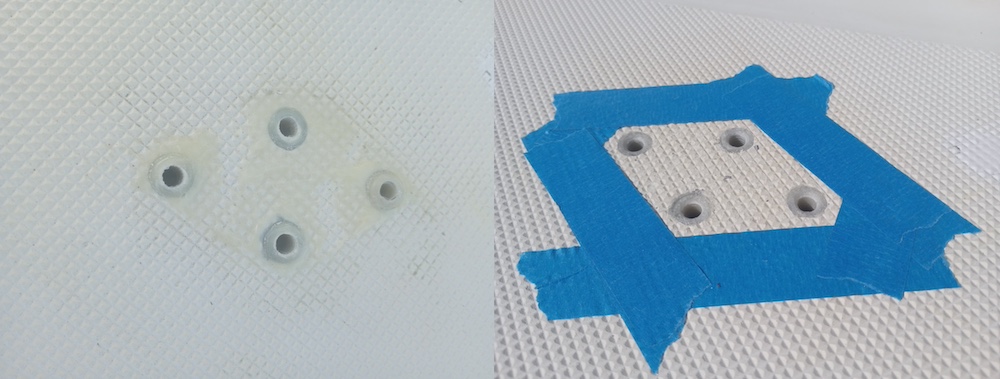

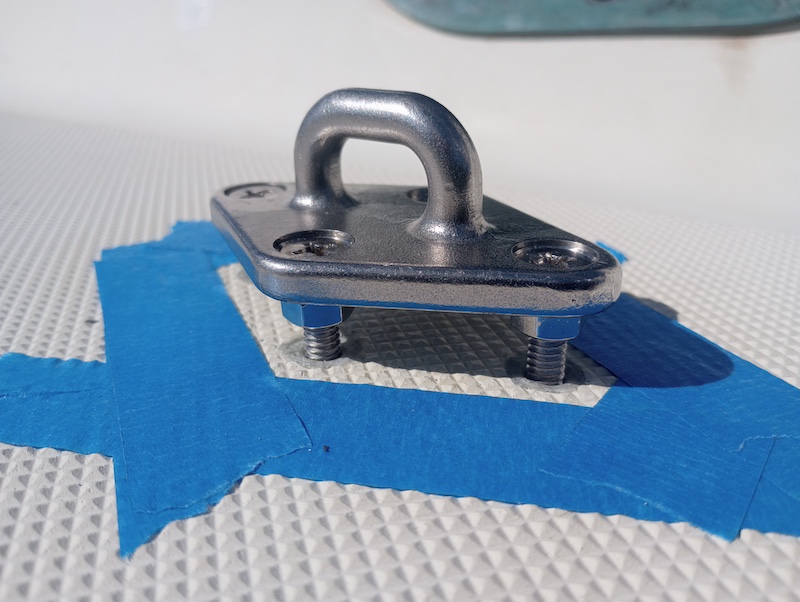

The diamond-shaped eye plates I would use required four 1/4-inch fasteners each, bolted through the deck. I determined the placement and mapped the plates’ holes. I drilled them oversized (1/2-inch) and prepped them as the how-to pros have written about many times before. I cut four small pieces of G-10 (1/4-inch inner diameter and 3/32-inch wall thickness), just a little longer than the deck was thick. I taped the underside of the deck holes to keep the forthcoming epoxy from oozing below and for the tubes to bottom out. Then, I fastened the screws to the plates with nuts, achieving two things: It rigidly lined the screws where they needed to be, and the nuts on the underside would help avoid inadvertently epoxying the plates to the deck. (Been there, done that.)

Using thickened epoxy, I coated the deck holes’ walls and the sleeves’ exteriors and gently inserted the sleeves into the holes. The hollow tubes had the advantage of letting potentially trapped air escape. I carefully put the diamond plate with the attached screws into the holes. (Yes, I dry-fit them first. Remember the best practices.) There was enough wiggle room for the sleeves to adjust placement but not so much as to draw in air or create voids. Epoxy oozed out on top, and some got inside the sleeves. Both were desirable to confirm thorough coverage and no trapped air. When it cured enough to set the sleeves, I gently removed the diamond plate so I could still clean up the epoxy with a cloth and acetone, from both the deck and screws.

Once the epoxy was fully cured, I used a Dremel tool with a grinding bit to remove the top of the sleeves (remember, I cut them a little long) and extra epoxy. I shaped the tops of the sleeves with a down-and-in bevel so later, when I attached the plates, the sealant would compress around the fastener. It was quick work to drive a 1/4-inch drill bit through the inside of the sleeves to clean out any epoxy. With the fasteners tightened, the tubes’ strength prevented deck compression.

Best practices include (but are not limited to) proper cleaning, drilling, thickener, backing plates, safety, sealant choices, and taping. The Resourceful Sailor encourages any do-it-yourselfer to review multiple sources when attempting a new-to-them project. Each source will approach a job differently, with ranging variances and circumstances. Arm yourself with as much information as possible to prepare for success. It is a boat, after all. Projects such as this can be very satisfying when you have the confidence of a job well done.

I recall my first epoxy jobs. They weren’t good. But I improved as I read more and gained more experience and confidence. Epoxy is a remarkable product. I went through the Northwest Passage on Breskell, a 50-ft cold-molded sloop built and captained by Olivier Huin. I called him the epoxy king. He ordered it by the barrels to build Breskell. During the passage, I witnessed many fixes, temporary and permanent, with it. Remember, keep your solutions safe and prudent, and have a blast.

To find out how The Resourceful Sailor’s DIY solutions hold up at sea, check out his presentation “Sailing With Josh & The Resourceful Sailor: A Flicka 20’s Pacific Odyssey” in Port Townsend on March 12. More here.

The Hylas H57 Now Available in San Diego

Sailagram: A Snapshot of February Sailing

Welcome to springtime! Our sailing days are getting longer and warmer, and we’re looking forward to seeing more boats out on the water. In the meantime, take a browse through the February Sailagram gallery, with a few boats from early March thrown into the mix — we didn’t want to have to wait a whole month to share them.

It’s a Left, Then a Left at the Bridge

After reading Andy Schwenk’s description of his Seattle-to-San Francisco passage (“Turkey Trot,” January), I thought I would share our somewhat different experience along that same route two months prior. Our less-qualified crew enjoyed five days of sailing. We also lost a crewman. But we ultimately got him back, with help from the US Coast Guard, and new Bay Area yacht club friends.

We sailed Alert, a 1982 Seguin 44. Designed by Olin Stephens II, she was one of the 13 built by Lyman-Morse in Thomaston, Maine. She won the 1985 Marion–Bermuda Race for her first owner. The second owner, a higher-up in one of the three-letter agencies, sailed her in Chesapeake Bay until September 2001, when other duties called.

The third owner, a retiring pilot, wanted the boat rerigged for singlehanded sailing so his wife could handle her in the event he was injured. So in 2002, he sailed Alert back to Lyman-Morse, which was owned then, as it had been in 1982, by his former college roommate, Cabot Lyman. I was advised that no friendship discounts were requested or granted. (If you want to see even more amazing contemporary things that L-M can do with these vessels, look up Magic or Aletheia.)

After sailing off the western coast of North and Central America for 15 years, Alert was transferred to a new owner, whose stewardship included interior reconditioning by the owner’s talented woodworking father (discounts included).

As the fifth steward, the only thing left for me to do was a drivetrain overhaul, which was accomplished largely by the great teams at Gallery Marine and Pacific Fiberglass in Seattle. I did successfully over-pitch the prop myself, which turned one haulout (and bridge-and-lock trip) into two.

By summer 2024, it was time to bring Alert south. My 30-year friend Mark was game. He’d spent a week during each of the two prior summers sailing Alert with me in the San Juan Islands. During those trips we’d managed repeated crossings of both the Strait of Georgia and the Strait of Juan de Fuca; how hard could a downhill trip be?

Latitude 38’s Spring Crew List Party Is Back!

Join us for our first spring crew list party in 5 years!

Bay View Boat Club, Thursday April 3, from 6 p.m. to 9 p.m. Tickets and info can be found here.